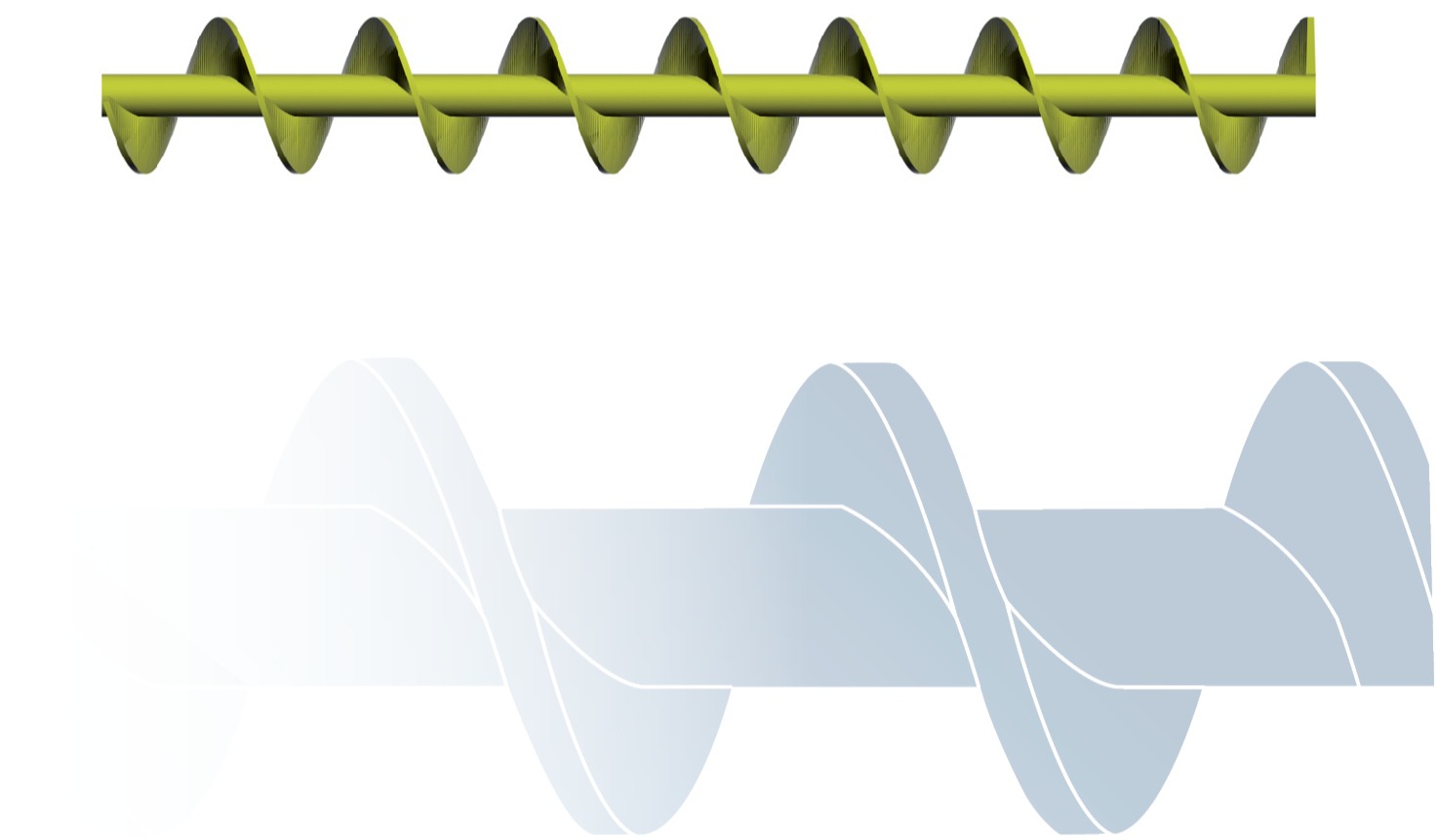

SINT®-Type Screws (Worm-On-Pipe)

Features, benefits and applications

1

SINT®ER or SINT®AL FDA-approved engineering polymer design

2

Available in standard lengths with square or variable pitch, with cylindrical or negatively

tapered centre pipe

3

Intermediate bearings and shaft couplings available on request