SG-Type Continuous Flighting

Features, benefits and applications

1

Manufactured in carbon steel or stainless steel 304/316

2

Standard dimensions available from stock

3

Available with right (RH) or left (LH) pitch

SG-Type Continuous Flighting

Manufactured in carbon steel or stainless steel 304/316

Standard dimensions available from stock

Available with right (RH) or left (LH) pitch

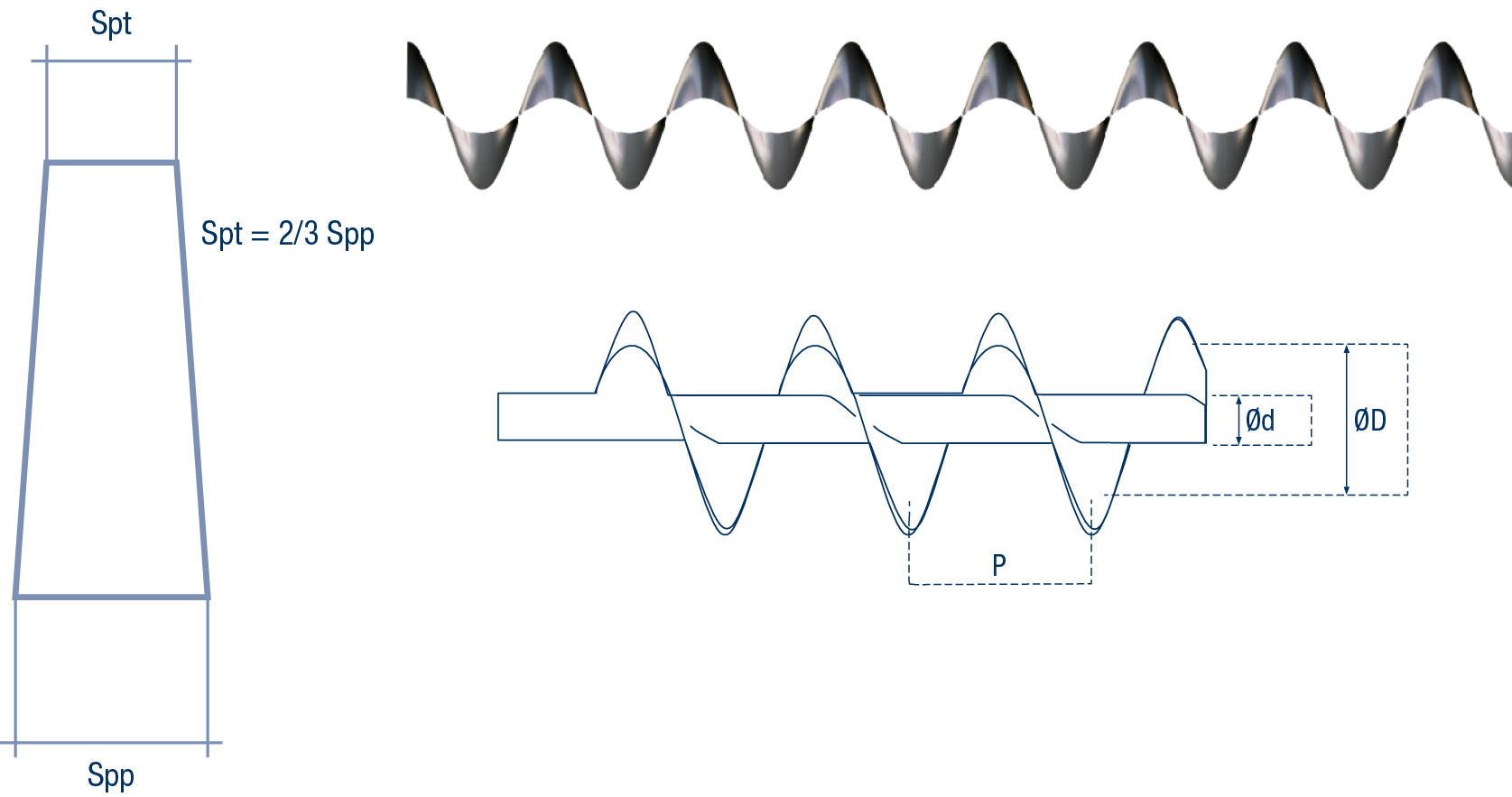

| Ø D (mm) | P (mm) | Ø d (mm) | Thickness Spp (mm) |

|---|---|---|---|

| From 100 to 700 mm | Up to 1/2 D | For standard tubes (inch sizes) | From 3 to 15 mm |

Continuous metal spirals, or screw conveyors, are crucial components in many industrial sectors. These mechanical devices are essential for the efficient transport of materials under various operating conditions.

SG-Type metal augers represent one of the most advanced and versatile solutions available on the market. Below, we will explore the main features, advantages and applications of SG-Type continuous metal augers.

SG-Type metal augers are manufactured using high-quality materials, such as carbon steel and 304/316 stainless steel. These materials give the augers exceptional strength and durability, making them suitable for various operating conditions.

SG-Type spirals are available in standard sizes ready for delivery, with the possibility of customised sizes on request. The available dimensions are as follows:

These specifications allow the spirals to be adapted to a wide range of applications, providing flexibility and versatility in use.

SG-Type spirals are available with either right (RH) or left (LH) pitch, offering further options to suit the specific needs of each application. This feature is important to ensure the correct movement of materials, depending on the required direction of rotation.

SG-Type metal spirals offer numerous advantages over other material transport solutions. Some of the main advantages include:

SG-Type continuous metal spirals find applications in numerous industrial sectors due to their efficiency and versatility. Below are some of the main applications:

In the food industry, continuous spirals are used to transport raw materials such as flour, sugar and other ingredients. The use of stainless steel ensures compliance with hygiene standards and resistance to corrosion.

Spirals are used to convey powders and granular materials, ensuring a continuous flow and preventing contamination of materials. 316 stainless steel is highly valued for its resistance to aggressive chemicals.

In the mining industry, metal spirals are essential for transporting heavy and abrasive materials such as ore and sand. Carbon steel offers the necessary strength to cope with complicated operating conditions.

Stainless steel continuous metal spirals are used to transport powders and chemical compounds in the production of pharmaceuticals. Corrosion resistance and ease of cleaning are crucial in this sector.

SG-Type augers are also used in waste management systems for the transport of solid and semi-solid materials. Their robustness and reliability make them ideal for this type of application.

SG-Type continuous metal augers are a highly efficient and versatile solution for conveying materials in various industries. Their carbon or stainless steel construction, together with different size and pitch options, make them suitable for a wide range of applications, ensuring efficiency and reliability at all times.

The production of SG-Type continuous metal spirals is an example of the dedication to innovation and customer satisfaction by our organisation, which since 2003 has been committed to providing high quality products tailored to the needs of customers worldwide.

For more information on SG-Type helical metal spirals and how they can improve the efficiency of your plant, please contact us. Our team of experts is always available to provide customised advice and technical support.

Drag & Drop Website Builder